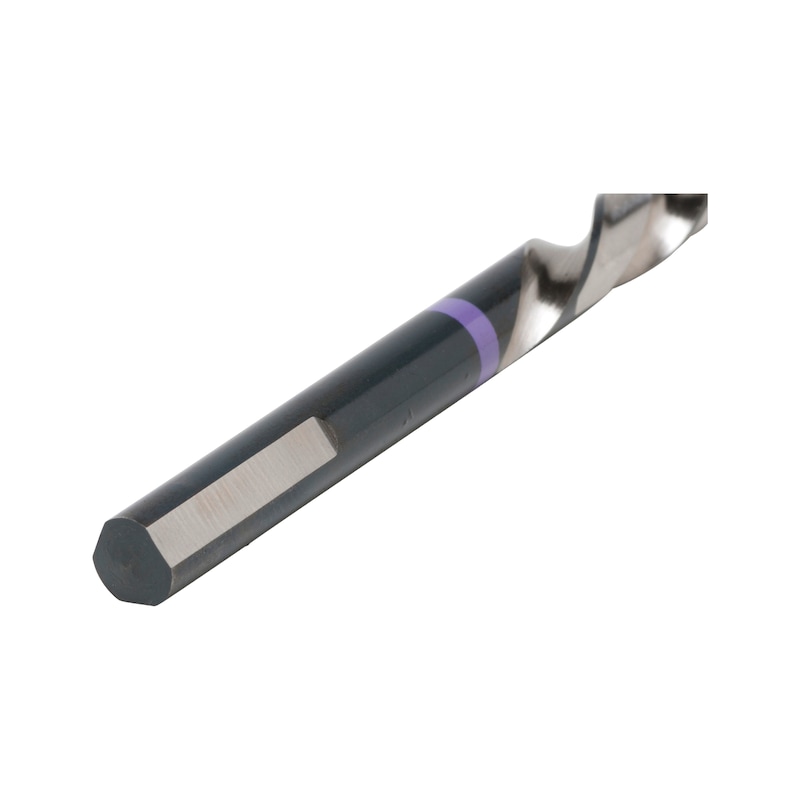

Twist drill bit HSCo DIN 338 MFD Speed

Twist drill bit HSCo DIN 338 MFD Speed

DRL-TWST-MET-DIN338-HSCO-MFDSPEED-D10,0

Art.-no. 0626931000

EAN 4056807135571

Register now and access more than 125,000 products

Up to 50 % faster than conventional twist drill bits with point thinning

Speed geometry

Optimal centring even when working on curved surfaces

135° tip angle and optimised cross web thinning

Low friction and fast chip removal

Exclusive Vario helix

3-flat shank (from dia. 4 mm):

- No spinning in the drill chuck: faster, more comfortable working

- Optimal power transmission

- Protects the drill chuck from damage

- Minimal effort required to loosen and tighten the drill chuck

Available exclusively from Würth

Product packaging made from 100 % PCR (recycled plastic from household waste) and 100 % recyclable

Datasheets(X)

Specially designed drill bit for a variety of different uses in cordless drills and hand drills

Suitable for machine type | Drill, Cordless screwdrivers, Pedestal drilling machine |

Material to be processed | Steel, Cast iron, Stainless steel, Titanium, Aluminium |

Quality | ZEBRA-Premium |

Standard / drilling depth | DIN 338 / 5xD |

Diameter (Ø) | 10.0 mm |

Length (l1) | 133 mm |

Chip flute length (l2) | 87 mm |

Shank diameter | 10.0 mm |

Shank style | 3-face shank |

Surface | Multiple refined |

Cutting material | HSCo |

Angle of the tip | 135 Degree |

Service life (points system) | 3 of 4 points |

Drilling speed (point system) | 4 of 4 points |

Bore hole quality (point system) ( ) | 3 of 4 points |

Versatility (points system) | 4 of 4 points |

Drilling behaviour (point system) | 4 of 4 points |

Suitable for drill (points system) | 4 of 4 points |

Suitable for cordless drills (points system) | 4 of 4 points |

Suitable for upright drilling machine (points system) | 4 of 4 points |

Self-centring | Yes |

Suitable for tensile strength up to | 1200 N/mm² |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, White cast iron, Stainless steels, sulphurated, Stainless steels, austenitic, Stainless steels, martensitic, Titanium, Spring steels, Magnesium alloys, Copper, low-alloyed, Bronze, short-chipping, Bronze, long-chipping, Brass, short-chipping, Brass, long-chipping, Plastics, thermoset, Plastics, thermoplastic, Alloyed tempering steels, Titanium alloys, Aluminium alloys, Aluminium, Aluminium casting alloys (<10% silicon), Aluminium wrought alloys |

| Cutting values | ||||||||||||

| For dia. 1.0-2.5 | ||||||||||||

| Material designation | Tensile strength | from dia. 1.0 | from dia. 2.0 | from dia. 2.5 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | ≤ 850 N/mm² | 30 | 40 | 9549 | 12732 | 0,016 | 4775 | 6366 | 0,050 | 3820 | 5093 | 0,063 |

| Unalloyed quenched and tempered steels | ≤ 850 N/mm² | 30 | 40 | 9549 | 12732 | 0,016 | 4775 | 6366 | 0,050 | 3820 | 5093 | 0,063 |

| Low-alloy quenched and tempered steels | ≤ 850 N/mm² | 30 | 40 | 9549 | 12732 | 0,016 | 4775 | 6366 | 0,050 | 3820 | 5093 | 0,063 |

| Unalloyed quenched and tempered steels | ≤ 1,000 N/mm² | 28 | 35 | 8913 | 11141 | 0,014 | 4456 | 5570 | 0,040 | 3565 | 4456 | 0,050 |

| Low-alloy quenched and tempered steels | ≤ 1,000 N/mm² | 28 | 35 | 8913 | 11141 | 0,014 | 4456 | 5570 | 0,040 | 3565 | 4456 | 0,050 |

| Alloyed quenched and tempered steels | ≤ 1,200 N/mm² | 12 | 18 | 3820 | 5730 | 0,012 | 1910 | 2865 | 0,032 | 1528 | 2292 | 0,040 |

| Nitriding steels | ≤ 1,200 N/mm² | 12 | 18 | 3820 | 5730 | 0,012 | 1910 | 2865 | 0,032 | 1528 | 2292 | 0,040 |

| Tool steels | ≤ 1,200 N/mm² | 12 | 18 | 3820 | 5730 | 0,012 | 1910 | 2865 | 0,032 | 1528 | 2292 | 0,040 |

| High-speed steels | ≤ 1,200 N/mm² | 12 | 18 | 3820 | 5730 | 0,012 | 1910 | 2865 | 0,032 | 1528 | 2292 | 0,040 |

| Stainless steels | ||||||||||||

| Stainless steels | ≤ 1,200 N/mm² | 10 | 14 | 3183 | 4456 | 0,012 | 1592 | 2228 | 0,032 | 1273 | 1783 | 0,040 |

| Titanium | ≤ 850 N/mm² | 6 | 10 | 1910 | 3183 | 0,008 | 955 | 1592 | 0,025 | 764 | 1273 | 0,032 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 850 N/mm² | 30 | 35 | 9549 | 11141 | 0,018 | 4775 | 5570 | 0,063 | 3820 | 4456 | 0,080 |

| Spheroidal graphite and malleable iron | ≤ 850 N/mm² | 26 | 30 | 8276 | 9549 | 0,018 | 4138 | 4775 | 0,063 | 3310 | 3820 | 0,080 |

| Non-ferrous metals | ||||||||||||

| Aluminium | ≤ 600 N/mm² | 40 | 60 | 12732 | 19099 | 0,018 | 6366 | 9549 | 0,063 | 5093 | 7639 | 0,080 |

| Plastics | ≤ 200 N/mm² | 20 | 30 | 6366 | 9549 | 0,016 | 3183 | 4775 | 0,050 | 2546 | 3820 | 0,063 |

| Key |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| For dia. 12.5-16.0 | |||||||||

| Material designation | Tensile strength | from dia. 12.5 | from dia. 16.0 | ||||||

| vc | n | f | n | f | |||||

| from | to | from | to | from | to | ||||

| Steels | |||||||||

| General structural steels | ≤ 850 N/mm² | 30 | 40 | 764 | 1019 | 0,200 | 597 | 796 | 0,250 |

| Unalloyed quenched and tempered steels | ≤ 850 N/mm² | 30 | 40 | 764 | 1019 | 0,200 | 597 | 796 | 0,250 |

| Low-alloy quenched and tempered steels | ≤ 850 N/mm² | 30 | 40 | 764 | 1019 | 0,200 | 597 | 796 | 0,250 |

| Unalloyed quenched and tempered steels | ≤ 1,000 N/mm² | 28 | 35 | 713 | 891 | 0,160 | 557 | 696 | 0,200 |

| Low-alloy quenched and tempered steels | ≤ 1,000 N/mm² | 28 | 35 | 713 | 891 | 0,160 | 557 | 696 | 0,200 |

| Alloyed quenched and tempered steels | ≤ 1,200 N/mm² | 12 | 18 | 306 | 458 | 0,125 | 239 | 358 | 0,160 |

| Nitriding steels | ≤ 1,200 N/mm² | 12 | 18 | 306 | 458 | 0,125 | 239 | 358 | 0,160 |

| Tool steels | ≤ 1,200 N/mm² | 12 | 18 | 306 | 458 | 0,125 | 239 | 358 | 0,160 |

| High-speed steels | ≤ 1,200 N/mm² | 12 | 18 | 306 | 458 | 0,125 | 239 | 358 | 0,160 |

| Stainless steels | |||||||||

| Stainless steels | ≤ 1,200 N/mm² | 10 | 14 | 255 | 357 | 0,125 | 199 | 279 | 0,160 |

| Titanium | ≤ 850 N/mm² | 6 | 10 | 153 | 255 | 0,100 | 119 | 199 | 0,125 |

| Cast metals | |||||||||

| Cast iron | ≤ 850 N/mm² | 30 | 35 | 764 | 891 | 0,250 | 597 | 696 | 0,315 |

| Spheroidal graphite and malleable iron | ≤ 850 N/mm² | 26 | 30 | 662 | 764 | 0,250 | 517 | 597 | 0,315 |

| Non-ferrous metals | |||||||||

| Aluminium | ≤ 600 N/mm² | 40 | 60 | 1019 | 1528 | 0,250 | 796 | 1194 | 0,315 |

| Plastics | ≤ 200 N/mm² | 20 | 30 | 509 | 764 | 0,200 | 398 | 597 | 0,250 |

| For dia. 6.3-10.0 | ||||||||||||

| Material designation | Tensile strength | from dia. 6.3 | from dia. 8.0 | from dia. 10.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | ≤ 850 N/mm² | 30 | 40 | 1516 | 2021 | 0,125 | 1194 | 1592 | 0,160 | 955 | 1273 | 0,200 |

| Unalloyed quenched and tempered steels | ≤ 850 N/mm² | 30 | 40 | 1516 | 2021 | 0,125 | 1194 | 1592 | 0,160 | 955 | 1273 | 0,200 |

| Low-alloy quenched and tempered steels | ≤ 850 N/mm² | 30 | 40 | 1516 | 2021 | 0,125 | 1194 | 1592 | 0,160 | 955 | 1273 | 0,200 |

| Unalloyed quenched and tempered steels | ≤ 1,000 N/mm² | 28 | 35 | 1415 | 1768 | 0,100 | 1114 | 1393 | 0,125 | 891 | 1114 | 0,160 |

| Low-alloy quenched and tempered steels | ≤ 1,000 N/mm² | 28 | 35 | 1415 | 1768 | 0,100 | 1114 | 1393 | 0,125 | 891 | 1114 | 0,160 |

| Alloyed quenched and tempered steels | ≤ 1,200 N/mm² | 12 | 18 | 606 | 909 | 0,080 | 477 | 716 | 0,100 | 382 | 573 | 0,125 |

| Nitriding steels | ≤ 1,200 N/mm² | 12 | 18 | 606 | 909 | 0,080 | 477 | 716 | 0,100 | 382 | 573 | 0,125 |

| Tool steels | ≤ 1,200 N/mm² | 12 | 18 | 606 | 909 | 0,080 | 477 | 716 | 0,100 | 382 | 573 | 0,125 |

| High-speed steels | ≤ 1,200 N/mm² | 12 | 18 | 606 | 909 | 0,080 | 477 | 716 | 0,100 | 382 | 573 | 0,125 |

| Stainless steels | ||||||||||||

| Stainless steels | ≤ 1,200 N/mm² | 10 | 14 | 505 | 707 | 0,080 | 398 | 557 | 0,100 | 318 | 446 | 0,125 |

| Titanium | ≤ 850 N/mm² | 6 | 10 | 303 | 505 | 0,063 | 239 | 398 | 0,100 | 191 | 318 | 0,100 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 850 N/mm² | 30 | 35 | 1516 | 1768 | 0,160 | 1194 | 1393 | 0,080 | 955 | 1114 | 0,250 |

| Spheroidal graphite and malleable iron | ≤ 850 N/mm² | 26 | 30 | 1314 | 1516 | 0,160 | 1035 | 1194 | 0,080 | 828 | 955 | 0,250 |

| Non-ferrous metals | ||||||||||||

| Aluminium | ≤ 600 N/mm² | 40 | 60 | 2021 | 3032 | 0,160 | 1592 | 2387 | 0,200 | 1273 | 1910 | 0,250 |

| Plastics | ≤ 200 N/mm² | 20 | 30 | 1011 | 1516 | 0,125 | 796 | 1194 | 0,160 | 637 | 955 | 0,200 |

| For dia. 3.15-5.0 | ||||||||||||

| Material designation | Tensile strength | from dia. 3.15 | from dia. 4.0 | from dia. 5.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | ≤ 850 N/mm² | 30 | 40 | 3032 | 4042 | 0,080 | 2387 | 3183 | 0,100 | 1910 | 2546 | 0,100 |

| Unalloyed quenched and tempered steels | ≤ 850 N/mm² | 30 | 40 | 3032 | 4042 | 0,080 | 2387 | 3183 | 0,100 | 1910 | 2546 | 0,100 |

| Low-alloy quenched and tempered steels | ≤ 850 N/mm² | 30 | 40 | 3032 | 4042 | 0,080 | 2387 | 3183 | 0,100 | 1910 | 2546 | 0,100 |

| Unalloyed quenched and tempered steels | ≤ 1,000 N/mm² | 28 | 35 | 2829 | 3537 | 0,063 | 2228 | 2785 | 0,080 | 1783 | 2228 | 0,080 |

| Low-alloy quenched and tempered steels | ≤ 1,000 N/mm² | 28 | 35 | 2829 | 3537 | 0,063 | 2228 | 2785 | 0,080 | 1783 | 2228 | 0,080 |

| Alloyed quenched and tempered steels | ≤ 1,200 N/mm² | 12 | 18 | 1213 | 1819 | 0,050 | 955 | 1432 | 0,063 | 764 | 1146 | 0,063 |

| Nitriding steels | ≤ 1,200 N/mm² | 12 | 18 | 1213 | 1819 | 0,050 | 955 | 1432 | 0,063 | 764 | 1146 | 0,063 |

| Tool steels | ≤ 1,200 N/mm² | 12 | 18 | 1213 | 1819 | 0,050 | 955 | 1432 | 0,063 | 764 | 1146 | 0,063 |

| High-speed steels | ≤ 1,200 N/mm² | 12 | 18 | 1213 | 1819 | 0,050 | 955 | 1432 | 0,063 | 764 | 1146 | 0,063 |

| Stainless steels | ||||||||||||

| Stainless steels | ≤ 1,200 N/mm² | 10 | 14 | 1011 | 1415 | 0,050 | 796 | 1114 | 0,063 | 637 | 891 | 0,063 |

| Titanium | ≤ 850 N/mm² | 6 | 10 | 606 | 1011 | 0,040 | 477 | 796 | 0,050 | 382 | 637 | 0,050 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 850 N/mm² | 30 | 35 | 3032 | 3537 | 0,100 | 2387 | 2785 | 0,125 | 1910 | 2228 | 0,125 |

| Spheroidal graphite and malleable iron | ≤ 850 N/mm² | 26 | 30 | 2627 | 3032 | 0,100 | 2069 | 2387 | 0,125 | 1655 | 1910 | 0,125 |

| Non-ferrous metals | ||||||||||||

| Aluminium | ≤ 600 N/mm² | 40 | 60 | 4042 | 6063 | 0,100 | 3183 | 4775 | 0,125 | 2546 | 3820 | 0,125 |

| Plastics | ≤ 200 N/mm² | 20 | 30 | 2021 | 3032 | 0,080 | 1592 | 2387 | 0,100 | 1273 | 1910 | 0,100 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!