VKP® Trio 1050 high-performance sealing tape

Sealing tape VKP Trio 1050 high performance

SEALTPE-RAL-VKP-TRIO1050-74/10-25MM-10M

Art.-no. 0875497410

EAN 4068362072635

Register now and access more than 125,000 products

Quick and easy window sealing in just one work step. Economic benefit due to enormous time savings

The outside is equipped with a water barrier, which is impermeable to driving rain up to at least 1,050 Pa and offers a high level of ingress protection in accordance with DIN 18542:2020-04

Middle section offers very good thermal and acoustic insulation

Polymer film on the inside

- Inside is fully airtight in accordance with DIN 18542:2020-04 and the EU Energy Performance of Buildings Directive 2020; meets the high requirements of passive and zero-energy houses

- Vapour diffusion gradient from the inside to the outside due to polymer film on the inside

- Suitable for quality-controlled installation in accordance with the requirements of RAL-Gütegemeinschaft für Fenster und Haustüren (German RAL Quality Assurance Association for Windows and Doors)

- Extreme airtightness and thermal insulation for maximum energy savings

- Very low emissions

Take into account structural movement and temporary changes in length of the existing joints when determining the appropriate tape size. The expansion speed of VKP® Trio 1050 high performance depends on the temperature. In high temperatures, store the tape in a cool location; in low temperatures, store in a warm location. Please use VKP® Plus for joints between solid components. We recommend using flexible tape or EPDM outdoor sealing tape in the bottom joint area. Carry out sufficient tests of your own on painted or sealed surfaces. No interactions with commercially available plaster mortar. The window is attached via spaced installation. Façade joints subject to high loads must be sealed using VKP® Plus.

EMICODE EC1plus: Very low emissions: The EMICODE classification system awards labels to construction products based on environmental and health compatibility. The lowest-emission products bear the EC1plus mark.

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications as well as storage and usage conditions, we do not assume any liability for a specific application result. Any technical information or advice provided by our free customer service shall be provided to the exclusion of any liability, unless the advice or information is part of our contractually agreed scope of services or the advisor was acting wilfully. We ensure the consistent quality of our products. We reserve the right to make technical changes and further developments to our products.

Datasheets(X)

Sealing of window and door joints, connecting joints of conservatories to the main building and other construction connections. Also ideal for passive and zero-energy houses.

Preparation:

- Roughly clean any dirt from the surfaces. A smooth coating is required in the case of unevenness.

- Cut off approx. 2 cm from the beginning and end of the tape.

- Allow approx. 2 cm/m of extra length when cutting the tape to size.

Installation on windows:

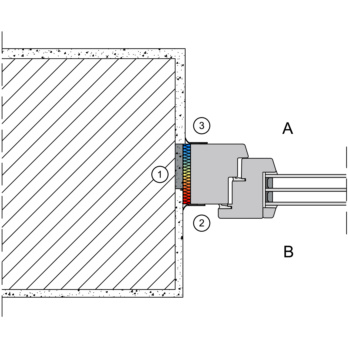

Remove the protective film from the self-adhesive strip and apply the tape to the window profile. Make sure that the inside and outside are positioned correctly (polymer film on the inside).

Formation in the corner area:

The tape will meet bluntly in the corners; compress longitudinally. Leaks must be avoided. Seal with Flexband adhesive, Wütop film adhesive or All-In-One connection adhesive, if available.

| |

Colour | Anthracite |

Backing material | PUR foam |

Width | 74 mm |

Thickness | 10 mm |

Min./max. joint width for watertightness in driving rain | 10-25 mm |

Length of roll | 10 m |

Min./max. processing temperature | 5 to 25 °C |

Min./max. temperature resistance | -30 to 80 °C |

Min. resistance against driving rain (pressure)/conditions | 1050 Pa / in accordance with DIN 18542-MF1 |

Building material class/conditions | B1 - Of low flammability / in accordance with DIN 4102 |

Stress group | MF1 |

Ultraviolet resistance | Yes, when installed to be resistant to driving rain |

Air permeability | 0 m³/hm |

Resistance against | Weather, with rain-tight installation |

Heat conductance λ | 0.048 W/(m*K) |

Heat conductance λ conditions | in accordance with DIN 52612 |

Range of applications | Sealing |

Shelf life from production/conditions | 18 Month / at 1°C to 20°C |

Sustainability | Pollutants / Emissions |