piasta® wing-type drilling screw, countersunk milling head with AW drive

Wing-piasta steel flake zinc silver cntrsnk hd AW

SCR-DBIT-WNG-CS-CUTHD-AW25-(RSI)-5,5X90

Art.-no. 0215885590

EAN 4047376279032

Register now and access more than 125,000 products

- Bimetal (A2 stainless steel/drilling tip made of case hardened steel)

- RUSPERT® coated (silver)

- With self-tapping thread

- Countersunk milling head for use with soft woods

AW drive system:

- Enhanced torque transmission

- Longer life

- Optimum centring

- Better mounting output thanks to fatigue-free screwing in; the required contact pressure for transmission of the torques is considerably lower

- Largest possible contact surface of bit in screw drive

- Even force distribution prevents damage to the surface-protection coating and therefore ensures better resistance to corrosion

- Wing-piasta screws must be appropriately tested for usability for each application case. Only install using application tools with a depth stop and claw coupling

- Drilling screws must be processed with a suitable drill driver (e.g. cordless drill driver with depth stop)

- The use of impact screwdrivers is not permitted

- Drilling screws must be attached perpendicular to the surface of the component

∅ 3.9/4.2/4.8 mm)

For use with wood and gypsum material boards and cement-bound mineral construction material boards with thin-walled steel profiles.

Datasheets(X)

CAD data (available after login)

How it works

- Force feeding of the screw is prevented by the wings drilling out the wood

- The core hole is drilled into the substructure. The wings break off upon contact with the metal

- The first few turns of the screw cut the thread, the remainder of the screw then screws into the thread

| |

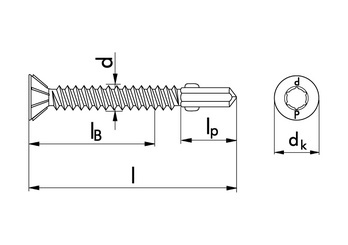

Nominal diameter (d) | 5.5 mm |

Length (l) | 90 mm |

Head diameter (dk) | 10.8 mm |

Head height (k1) | 4.4 mm |

Drill tip length (lp) | 11 mm |

Other standard | Company standard |

Material | Bimetal |

Surface | Flake zinc silver |

Head type | Countersunk milling head |

Internal drive | AW25 |

Thread type | Self-tapping screw thread |

Min. recommended substructure thickness | 2.0 mm |

Max. material thickness to be drilled through (metal) (lU) | 5 mm |

Max. attachment thickness (lB) | 70 mm |

Min./max. recommended installation speed (idling) | 1200-1800 rpm |

Approval | No |

RoHS-compliant | Yes |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!